Self Tapping Nuts

Self Tapping Nuts Specification

- Standard

- DIN 7965 / ISO 1479 / IS 4762

- Diameter

- M3 to M16 (custom sizes available)

- Material

- Carbon steel, stainless steel, brass

- Surface

- Zinc plated, galvanized, plain or phosphated finish

- Feature

- High gripping force, easy installation, corrosion resistance

Self Tapping Nuts Trade Information

- Payment Terms

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 20000 Per Month

- Delivery Time

- 1-4 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- coton box gunny bags

- Main Domestic Market

- All India

About Self Tapping Nuts

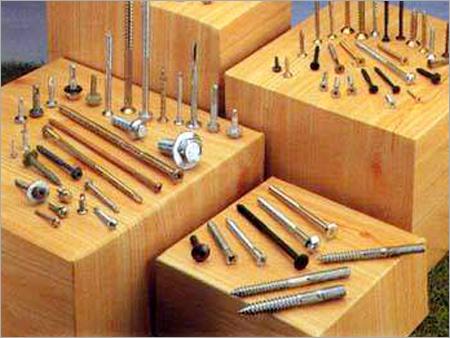

Self Tapping Nuts

Judicial mix of men & machinery has enabled us in meeting the requirements of our clients by offering a large range of Self Tapping Nuts. These nuts are widely used to fasten the sheet metal composite material, wood and plastics. Advance technology and latest machinery are used while manufacturing these Self Tapping Nuts, that ensure their characteristics like dimensional accuracy, high tensile strength and rugged design. We adhere to the parameters of the national and international quality standards to provide the clients with utmost satisfaction in terms of quality.

STANDARD REF

It can be supply as per IS, BS, JIS, ISO, and DIN Standard. Some non Standard as per drawing or sample.

M. S. Sp,wire cash Harden with Zinc platted, SS Sp wire and Brass.

Above Hardware items used at Electric and Electronics Instruments, T. V. Computer, Zerox Copy machine, Automobile, Bus Bodi Divi. Textile, Airconditon, Washing Machine, Refrigerator plants and other service Industries.

Comprehensive Application Range

These self tapping nuts excel in numerous fields, from automotive manufacturing to the assembly of electrical enclosures and sheet metal fabrication. Their adaptability extends to plastic components, making them an ideal solution for industries requiring secure, long-lasting fastening on various substrates.

Robust Construction and Finish

Constructed in carbon steel, stainless steel, or brass, self tapping nuts offer durability and performance. Finishes like zinc plating and galvanization provide superior corrosion resistance, meeting up to 240 hours of salt spray testing. Their colorsilver, yellow, or blackdepends on the chosen protective finish.

Installation and Packaging Efficiency

With a design that facilitates quick installation and high gripping force, these nuts streamline assembly processes. Theyre supplied in bulk-packed cartons or custom packaging as specified, ensuring convenient handling for manufacturers, suppliers, and traders across India.

FAQs of Self Tapping Nuts:

Q: How are self tapping nuts installed in sheet metal or plastic components?

A: Self tapping nuts are inserted into pre-punched holes, allowing their threads to cut into the surrounding material as theyre tightened. This enables fast and secure installation without the need for pre-threading, making the process efficient for sheet metal or plastic applications.Q: What benefits do self tapping nuts offer for automotive and electrical assemblies?

A: Their high gripping force, corrosion-resistant surface, and ease of installation make self tapping nuts ideal for automotive and electrical uses. They provide strong, durable fastening solutions that withstand vibration and harsh environments, ensuring assembly integrity.Q: When is it advantageous to use zinc plated or galvanized finishes on self tapping nuts?

A: Zinc plated or galvanized finishes are chosen when enhanced corrosion resistance is needed, such as in automotive, outdoor, or damp environments. These finishes protect the fastener for up to 240 hours in salt spray testing, extending the lifespan of assemblies.Q: Where can self tapping nuts be sourced in custom sizes and materials?

A: Manufacturers, suppliers, and traders across India offer self tapping nuts in various diameters (M3 to M16) and materials like carbon steel, stainless steel, or brass. Custom sizing and materials can be specified at the time of order to meet project needs.Q: What is the process for selecting the appropriate thread type for self tapping nuts?

A: Thread type selection depends on the application requirementsmetric threads for standard global compatibility and UNC/UNF threads for specific regional or industry needs. Reference to standards such as DIN 7965, ISO 1479, or IS 4762 can guide appropriate thread choice.Q: How does the shape and flange design of the nut impact its usage?

A: Round nuts with a hex flange or a hex body enhance torque transmission and gripping strength during installation, reducing the risk of slippage. The design contributes to better load distribution and minimizes material deformation under tightening.Q: What packaging options are available for bulk or project-based procurement?

A: Self tapping nuts are typically bulk packed in sturdy cartons, but manufacturers can offer custom packaging solutions as specified by the buyer, ensuring safe transit, efficient handling, and convenience for large or bespoke orders.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

GST : 27AGVPS7249C1ZR

|

ZENITH INDUSTRIAL PRODUCTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry